Kev piav qhia

Product Description

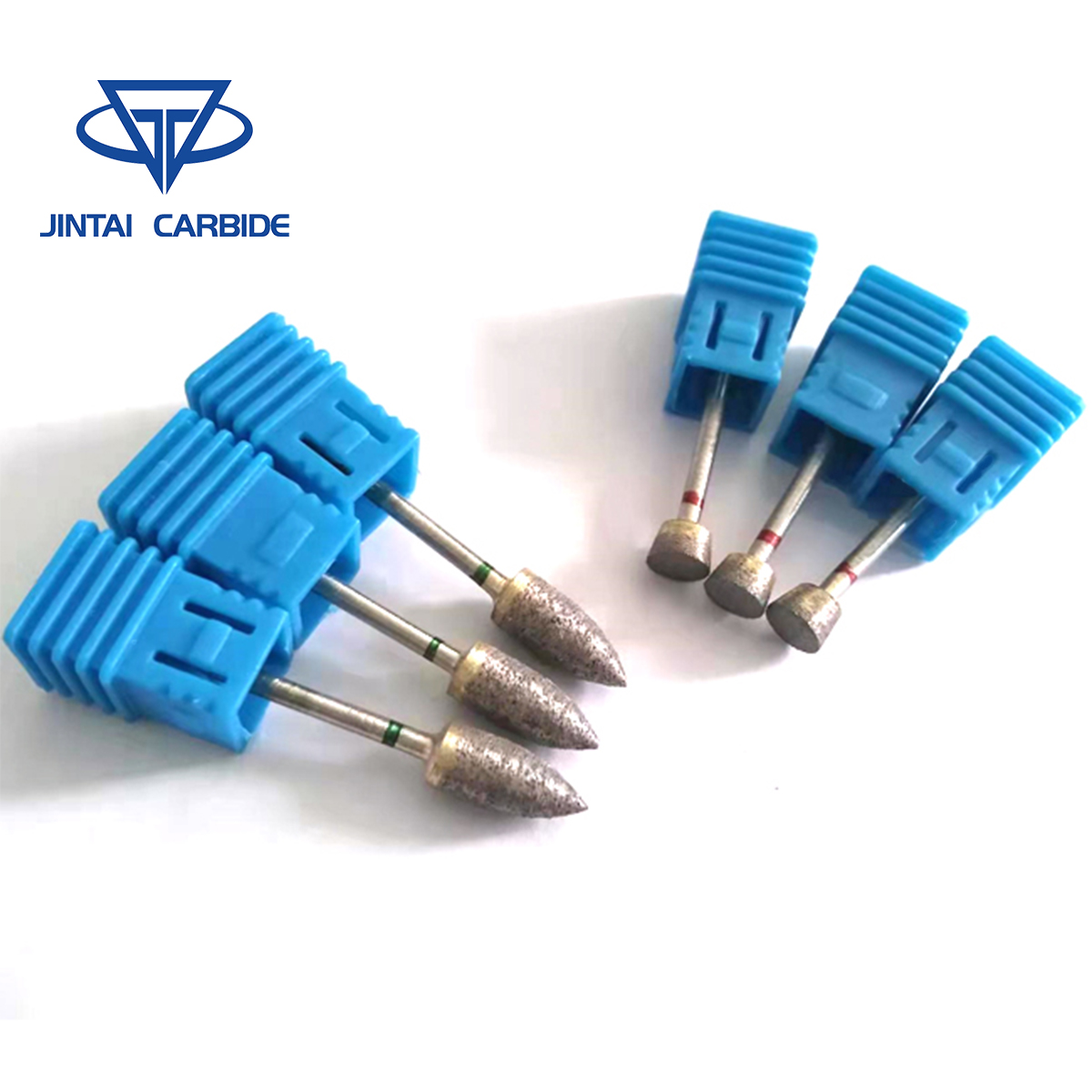

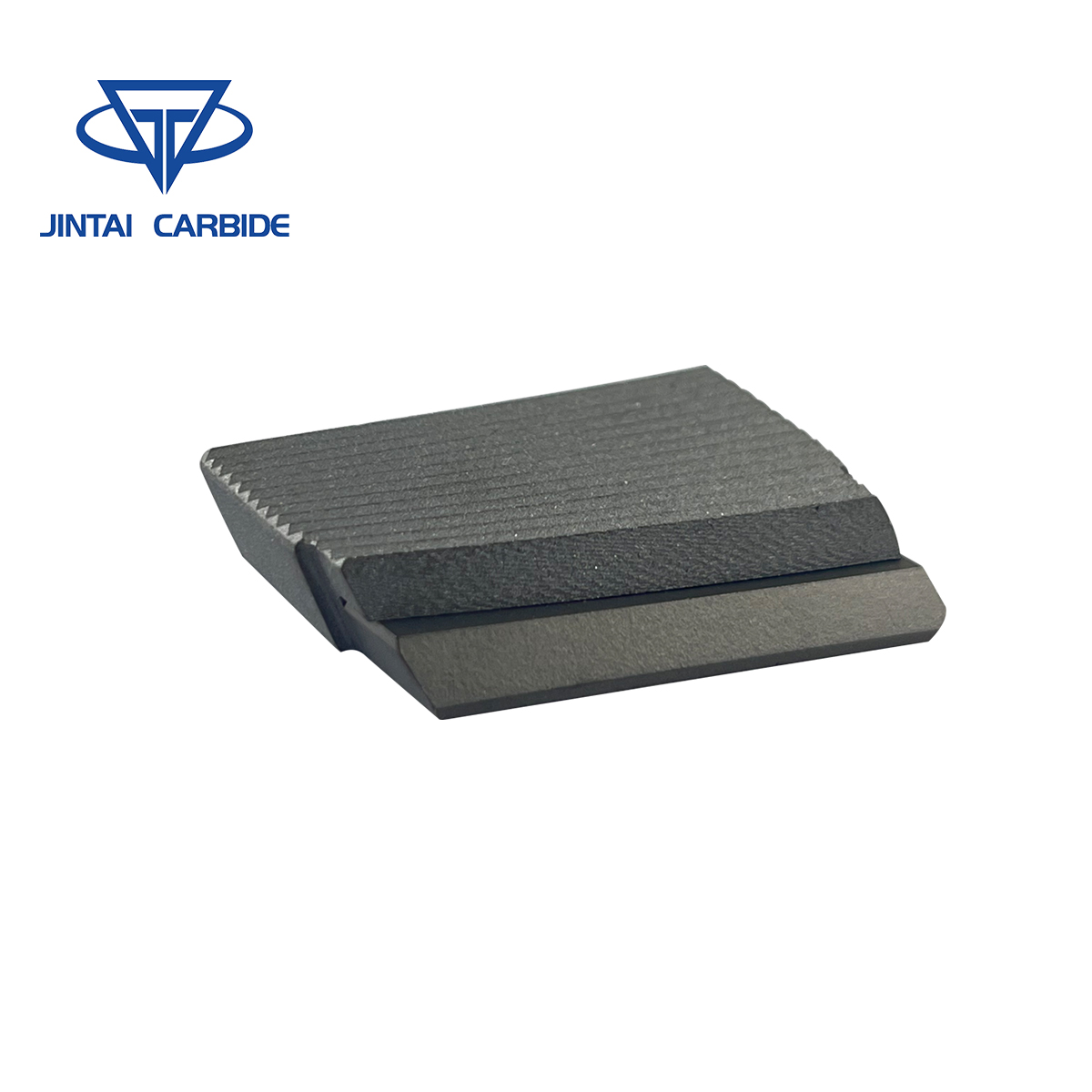

Cemented carbide pas nrig muaj qhov ncaj ncaj, zoo heev hardness, thiab ruaj khov toughness.

End mills, reamers thiab gravers raug pom zoo.Kev ua tau zoo heev rau kev kub ceev txiav.Haum rau kev txiav hardened steel, aluminium alloy thiab titanium alloy.Peb muab kev cai tsim, ze-net-puab, premium inserts blanks hauv cemented carbide - tseem hu ua Tungsten carbide lossis khoom carbide.

Khoom muaj pes tsawg leeg:

1. Lub cev muaj zog:

A) Hardness ntau dua lossis sib npaug rau 92.8 HRA;

B) Qhov ceev ntau dua lossis sib npaug li 14.2 g / cm³;

C) TRS ntau dua lossis sib npaug rau 4200 N / mm²;

D) Dawb ntawm ETA theem mob;

E) Tsis muaj kab mob los ntawm lwm yam khoom;

F) Porosity = A00 / B00 / C00 ;

G) Uniform thiab sib xws grain loj.Tsis muaj qhov loj me tuaj yeem loj dua li teev.

H) Chromium carbide grain kev loj hlob inhibitor nkaus xwb.

2.Tag nrho cov ntau lawm, txheej yog siv nyob rau hauv lub teb chaws Yelemees, Switzerland, ua khoom siv;

3.Nws tau thov txiav tsawg dua 60HRC;

Feature

1. 100% nkauj xwb raw khoom.

2. Ntau hom qib yog availalbe raws li cov neeg siv khoom thov.

3. peb muaj cov kws tshaj lij cov kab ntau lawm thiab inspeciton equipments los xyuas kom meej cov khoom zoo.

4. Precision av thiab cov txheej txheem polishing siab

5. High hnav tsis kam, siab hardness thiab cuam tshuam toughness

6. Advanced technology, precision sib tsoo.

Cov npe qeb

| Qib | ISO Code | Physical Mechanical Properties (≥) | Daim ntawv thov | ||

| Qhov ntom g/cm3 | Hardness (HRA) | TRS N / hli 2 | |||

| YG 3 X | k05 ua | 15.0-15.4 Nws | ≥91.5 | ≥1180 | Haum rau precision machining ntawm cam khwb cia hlau thiab non-ferrous hlau. |

| YG 3 | k05 ua | 15.0-15.4 Nws | ≥90.5 | ≥1180 | |

| YG 6 X | K10 | 14.8-15.1 Nws | ≥91 | ≥1420 | Haum rau precision machining thiab semi-tiav ntawm cam khwb cia hlau thiab non-ferrous hlau, nrog rau kev ua ntawm manganese steel thiab quenched steel. |

| YG6A | K10 | 14.7-15.1 Nws | ≥91.5 | ≥1370 | |

| YG 6 | K20 | 14.7-15.1 Nws | ≥89.5 | ≥1520 | Haum rau semi-tiav thiab ntxhib machining ntawm cam khwb cia hlau thiab lub teeb alloys, thiab kuj yuav siv tau rau ntxhib machining ntawm cam khwb cia hlau thiab tsawg alloy steel. |

| YG8N | K20 | 14.5-14.9 Nws | ≥89.5 | ≥1500 | |

| YG 8 | K20 | 14.6-14.9 Nws | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 Nws | ≥88 | ≥1710 | Haum rau inlaying rotary cuam tshuam pob zeb drilling thiab teb cuam tshuam pob zeb drilling khoom. |

| YG11C | K40 | 14.0-14.4 Nws | ≥86.5 | ≥2060 | Haum rau inlaying chisel-zoo li tus los yog conical hniav khoom rau hnyav-duty pob zeb drilling tshuab rau tackle nyuaj pob zeb formations. |

| YG 15 | K30 | 13.9-14.2 Nws | ≥86.5 | ≥ 2020 | Haum rau kev sim tensile ntawm steel tuav thiab steel kav nyob rau hauv siab compression ratios. |

| YG 20 | K30 | 13.4-13.8 Nws | ≥85 | ≥2450 | Haum rau ua stamping tuag. |

| YG20C | K40 | 13.4-13.8 Nws | ≥82 | ≥2260 | Haum rau kev ua kom txias stamping thiab txias nias tuag rau kev lag luam xws li cov qauv, bearings, cov cuab yeej, thiab lwm yam. |

| YW1 | M10 | 12.7-13.5 Nws | ≥91.5 | ≥1180 | Haum rau precision machining thiab semi-tiav ntawm stainless hlau thiab dav hlau alloy steel. |

| YW 2 | M20 | 12.5-13.2 Nws | ≥90.5 | ≥1350 | Haum rau semi-tiav ntawm stainless hlau thiab tsis tshua muaj hlau alloy. |

| YS 8 | M05 | 13.9-14.2 Nws | ≥92.5 | ≥1620 | Haum rau precision machining ntawm hlau-raws li, nickel-raws li high-temperature alloys, thiab high-strength steel. |

| YT5 | P30 | 12.5-13.2 Nws | ≥89.5 | ≥1430 | Haum rau hnyav-duty txiav steel thiab cam khwb cia hlau. |

| YT15 | P10 | 11.1-11.6 Nws | ≥91 | ≥1180 | Haum rau precision machining thiab semi-tiav ntawm steel thiab cam khwb cia hlau. |

| YT 14 | P20 | 11.2-11.8 Nws | ≥90.5 | ≥1270 | Haum rau precision machining thiab semi-tiav ntawm steel thiab cam khwb cia hlau, nrog nruab nrab pub tus nqi.YS25 yog tsim tshwj xeeb rau kev ua haujlwm milling ntawm steel thiab cam khwb cia hlau. |

| YC45 | P40/P50 | 12.5-12.9 Nws | ≥90 | ≥2000 | Haum rau cov cuab yeej ua haujlwm hnyav, muab cov txiaj ntsig zoo hauv kev sib hloov ntawm cov castings thiab ntau yam steel forgings. |

| YK 20 | K20 | 14.3-14.6 Nws | ≥86 | ≥2250 | Haum rau inlaying rotary cuam tshuam pob zeb drilling cov khoom thiab drilling hauv cov pob zeb nyuaj thiab nyuaj. |

Kev txiav txim

Txheej txheem ntau lawm

Ntim